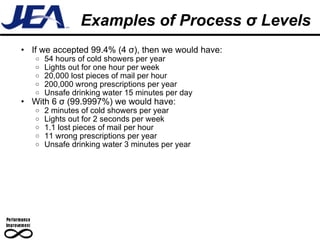

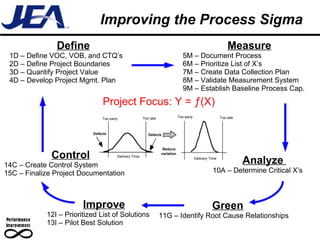

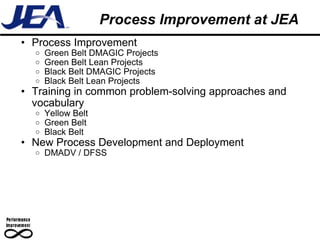

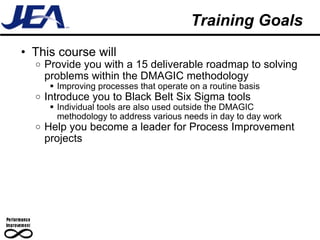

The document provides an introduction to Six Sigma, defining it as a management philosophy that aims to reduce defects in processes. It discusses the Six Sigma definition and process, including the DMAIC and DMADV methodologies. It also outlines the roles of Green Belts, Black Belts, and Master Black Belts in executing Six Sigma projects and processes.